Lesson 2 – Polyurethane & Nylon Pads

What You Will Learn

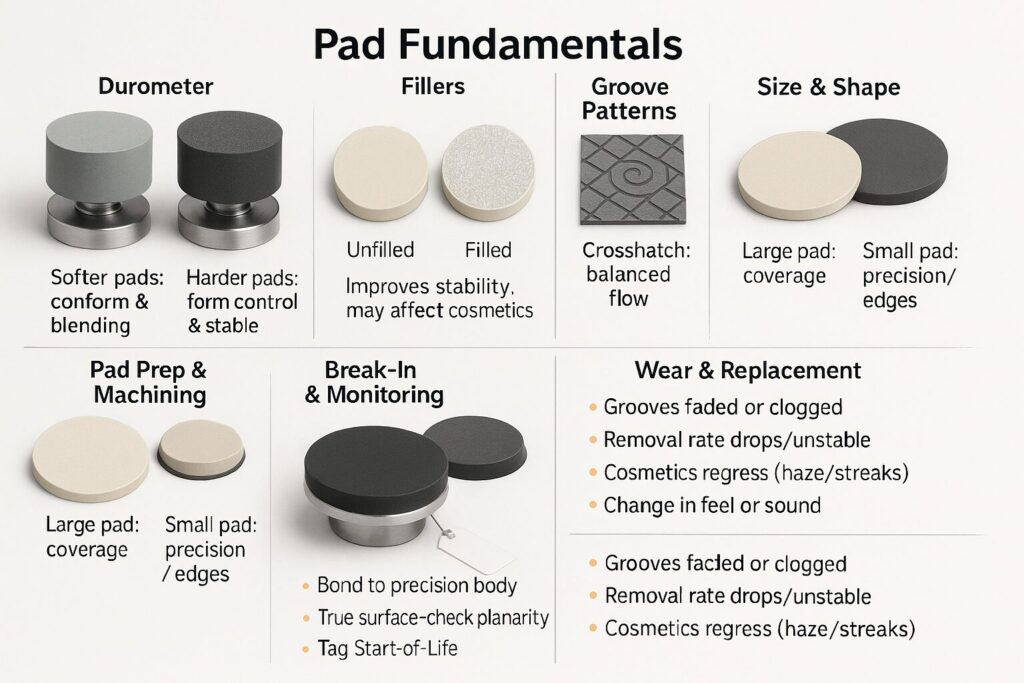

- List pad properties: durometer, fill, groove pattern, size, and shape

- Explain why precision pad machining and bodies are required

- Match pad type to removal rate, form control, and cosmetic goals

- Recognize pre-grooved versus custom-grooved strategies

- Describe pad break-in and replacement signals

Pad Fundamentals

Polyurethane and nylon pads form the working interface between the polishing tool and the optical surface. They control how energy, motion, and slurry interact across the contact zone. Because of this critical role, every pad must be mounted on a precision-machined body and surfaced to the correct geometry before polishing begins.

Polyurethane and nylon pads form the working interface between the polishing tool and the optical surface. They control how energy, motion, and slurry interact across the contact zone. Because of this critical role, every pad must be mounted on a precision-machined body and surfaced to the correct geometry before polishing begins.

Pads are available in a wide range of durometers (a measure of hardness), compositions, and surface features. Softer polyurethane pads tend to conform more readily to part curvature and blend micro-surface variations, while harder pads maintain better form control and localized correction. Nylon pads, being stiffer and more fibrous, are often used when higher removal rates are needed or when rough polishing steps precede finer finishing.

Pre-grooved pad designs, such as spiral or crosshatch patterns, assist in managing slurry transport, debris evacuation, and temperature control. For more specialized work, custom groove patterns can be machined to optimize removal uniformity or to manage unique hydrodynamic conditions on complex parts. Storage and handling are equally critical – pads should remain clean, dry, and shielded from ultraviolet light or contaminants that may alter their compliance before use.

Selecting Pads

Choosing the right pad depends on the balance between removal rate, form accuracy, and surface cosmetics. Several physical properties guide this selection:

Durometer

Pad hardness is one of the most influential parameters. Softer pads (lower durometer) conform to small-scale form errors, helping to improve cosmetic blending and reduce mid-spatial frequency errors. Harder pads (higher durometer) maintain pressure uniformity over a defined contact zone and are better for deterministic correction and stable removal profiles.

Fillers

Some pads incorporate fillers such as glass microspheres or polymer particulates. These additives modify stiffness, wear resistance, and micro-texture. Filled pads tend to exhibit more stable long-term removal behavior but may increase the risk of fine scratching if not paired with compatible slurry and process parameters.

Groove Patterns

Grooves serve both mechanical and thermal functions. They allow fresh slurry to enter and spent slurry to exit the contact zone, while also minimizing hydroplaning. Crosshatch grooves offer balanced flow in multiple directions, whereas spiral grooves help control slurry movement toward the center or edge. Deeper grooves increase exchange efficiency but may cause pattern imprinting if tool pressure or dwell is excessive.

Size and Shape

Pad size determines the contact area and removal footprint. Larger pads average out small-scale irregularities but may obscure localized form deviations. Smaller pads, on the other hand, are suited for zonal correction or edge blending where spatial resolution matters more than throughput.

Pad Preparation and Machining

Before installation, the pad surface must be trued to match the tool body geometry. This involves precise machining or lapping to ensure planarity and uniform thickness. Pads are typically bonded to their backing plates using adhesives designed to withstand mechanical stress and chemical exposure from polishing slurries. After bonding, the pad’s surface is inspected for defects such as trapped air, poor adhesion, or uneven thickness.

A labeled “start-of-life” tag helps track usage cycles. Because pad performance changes with wear and slurry exposure, operators must monitor how the pad’s removal rate stabilizes during its initial break-in period.

Break-In and Performance Monitoring

The break-in phase is where pad behavior transitions from initial variability to a steady-state condition. During this time, removal rate, surface temperature, and frictional load should be monitored closely. A stable removal rate and consistent cosmetic appearance indicate that the pad has fully conditioned.

Operators should also watch for signs of hydrodynamic instability, such as excessive slurry film buildup or surface overheating. Consistent temperature readings across the pad and part are indicators of uniform slurry behavior.

Pad Wear and Replacement

Pad Wear and Replacement

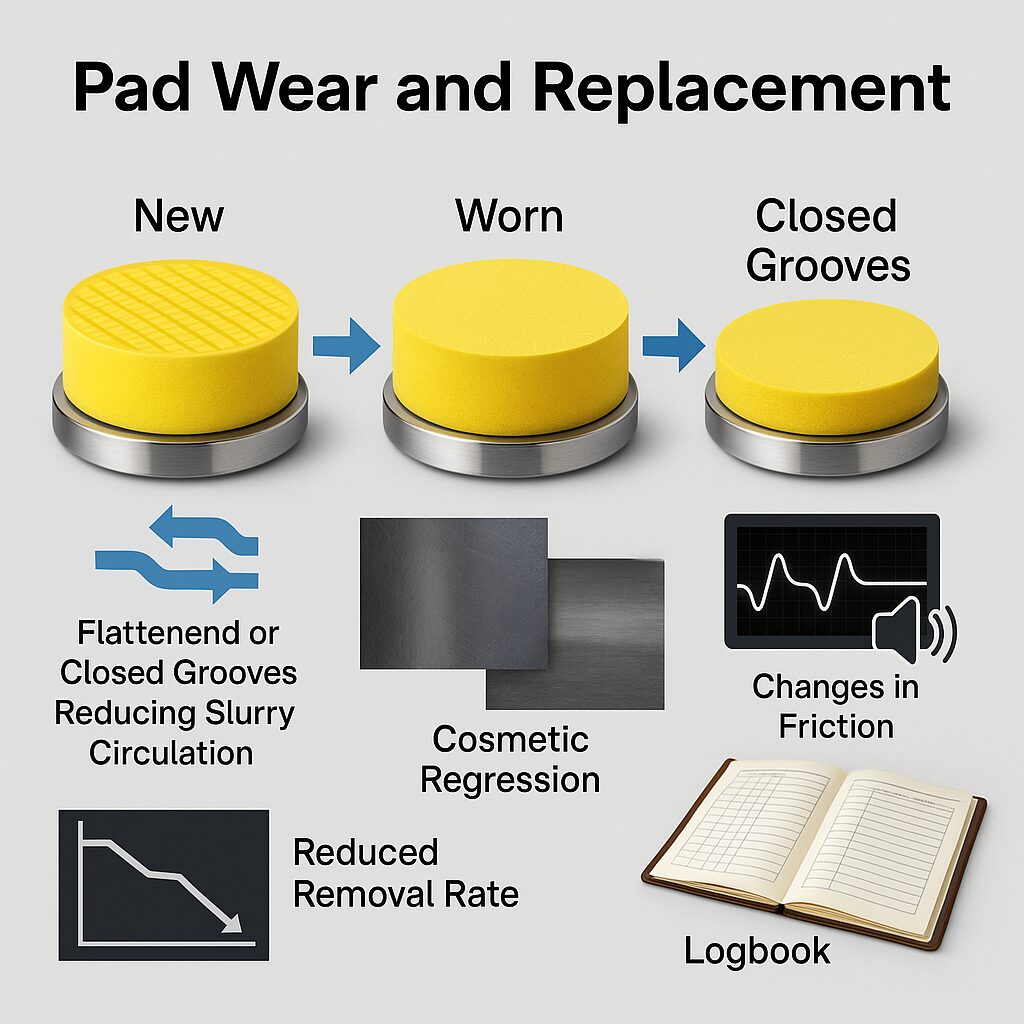

Pads degrade over time through mechanical abrasion and chemical exposure. Visual inspection and metrology feedback help determine when to replace a pad. Common indicators of end-of-life include:

- Flattened or closed groove patterns reducing slurry circulation

- Reduced removal rate or unstable dwell performance

- Cosmetic regression such as haze, streaks, or repeatable patterning

- Audible or tactile changes in friction during operation

When any of these symptoms appear, the pad should be resurfaced or replaced to restore stable, predictable polishing behavior. Proper recordkeeping of pad lot numbers, hours of use, and performance metrics ensures traceability and supports process repeatability.

Summary

Polyurethane and nylon pads are not passive consumables; they are active process elements that determine removal dynamics, form accuracy, and cosmetic finish. Selecting the correct pad, preparing it with precision, and maintaining it through disciplined inspection and replacement cycles ensures reliable, high-quality optical results. The interplay of durometer, groove geometry, and slurry behavior defines the art and science of pad management in CNC polishing.