Lesson 1- Introduction to Polishing

What You Will Learn

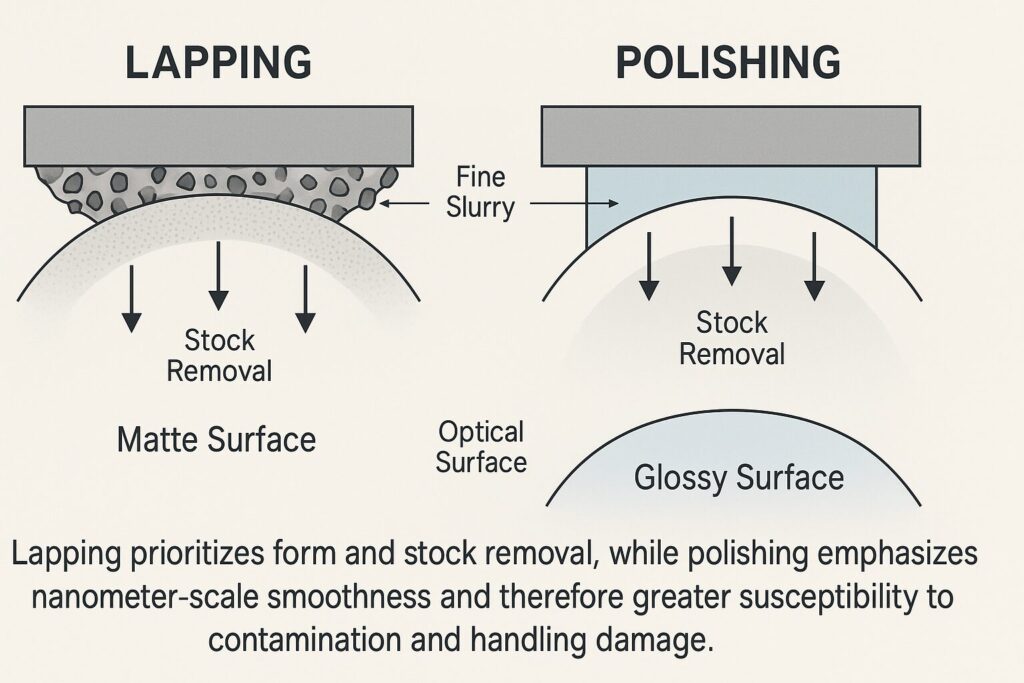

- Differences between lapping and polishing

- Why polished optical surfaces are vulnerable

- How to prevent staining and damage

- The role of surface quality in optical performance

Polishing is the precision finishing step that transforms a shaped optic into a functional optical surface. Lapping/Grinding establishes the figure shape by removing stock with powdered abrasives and a liquid carrier that leaves a frosted, diffuse finish that cannot transmit or reflect light efficiently. Polishing utilizes a finer abrasive mixed slurry, that utilizes a softer compliant medium such as pitch or polyurethane fabric. Polishing is also a lapping process that reduces surface roughness from the micron regime typical of lapping down to single nanometer or better. The polishing process smooths, high frequency surface roughness and sub-surface damage, making the optical surface far more revealing of defects and contamination.

A lapped surface can mask minor handling marks in its texture, but a polished surface is optically “honest.” Fingerprints introduce oils and salts; these can chemically react with optical substrate materials and result in permanent stains on the optical surface. Condensation moisture from breathing or spittle from talking can deposit moisture that can also react with certain glasses; airborne dust can embed during wiping and create sleeks or faint scratches. Because the surface roughness is so low, even very small particles or films create visible defects that can cause measurable scatter, haze, or loss of performance.

A lapped surface can mask minor handling marks in its texture, but a polished surface is optically “honest.” Fingerprints introduce oils and salts; these can chemically react with optical substrate materials and result in permanent stains on the optical surface. Condensation moisture from breathing or spittle from talking can deposit moisture that can also react with certain glasses; airborne dust can embed during wiping and create sleeks or faint scratches. Because the surface roughness is so low, even very small particles or films create visible defects that can cause measurable scatter, haze, or loss of performance.

Protecting finished optical surfaces begins with disciplined handling and a clean work environment. Operators should handle parts by the edges with clean, lint-free gloves (latex or Nitrile) and minimize speaking directly over exposed surfaces. Work areas benefit from controlled humidity and effective dust control so that slurry residues and films do not dry on the surface of the optics. When cleaning is required, the sequence should use approved solvents and wipes appropriate to the substrate being cleaned, using light, even strokes that avoid trapping particles and dragging them across the surface. After cleaning, optics should be staged on non-abrasive supports and covered to prevent re-deposition while they await inspection.

From a metrology perspective, polishing is not merely cosmetic; it determines how the optical surface transmits or reflects light. Lower roughness reduces wide-angle scatter and improves signal in interferometry and scatterometry. Contamination-free surfaces yield more repeatable measurements. In practice, this means that polishing quality and handling discipline directly influence not just how an optic looks, but how it measures, and ultimately how it performs in service.